Shenzhen Shixinghong Precision Machinery Equipment Co., Ltd. / 粤ICP备11036526号 / Powered by www.300.cn

Page view:

Gantry machining center (width 2300-2800mm)

Quantity

-

+

Description

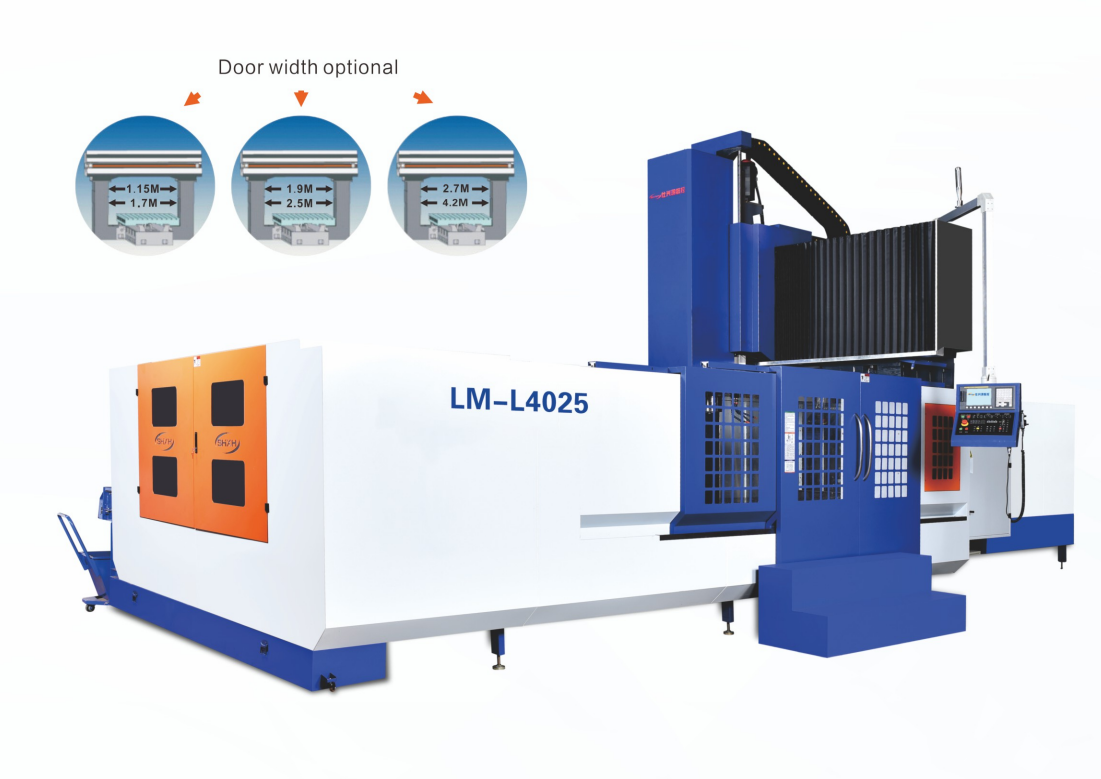

▌ Optional door width

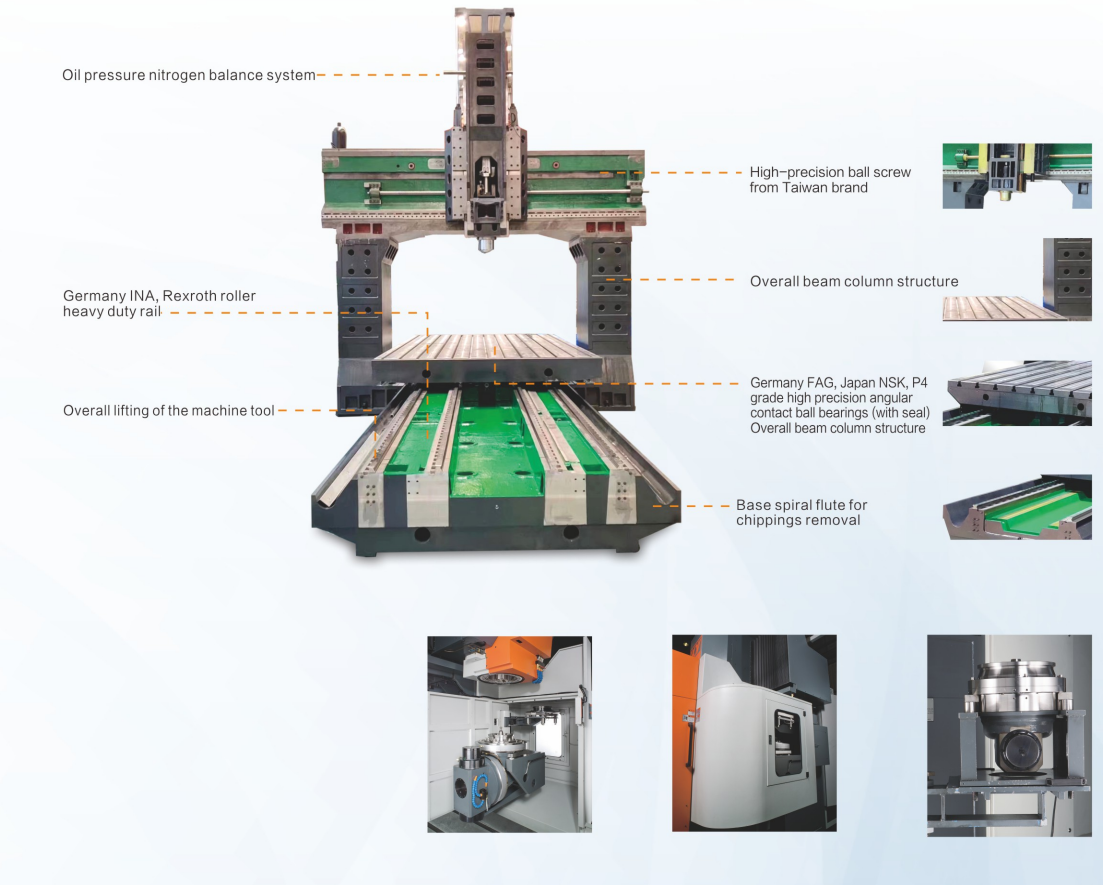

▌ Fuselage structure details

▌ technical parameter

| Gantry Width (mm) | 2300 | 2300(Z-axis of rigid rail,4 linear rails of Z-axis optional) | 2500 | 2700 | 2800(Z-axis of rigid rail,4 linear rails of Z-axis optional) | |||||||||||||||

| Machine data / Model number | LM-L3023 | LM-L4023 | LM-L5023 | LM-L6023 | LM-L3023R | LM-L4023R | LM-L6023R | LM-L8023R | LM-L3025 | LM-L4025 | LM-L5025 | LM-L6025 | LM-L3027 | LM-L4027 | LM-L5027 | LM-L6027 | LM-L3028R | LM-L4028R | LM-L6028R | LM-L8028R |

| Size of the table (Length×width) (mm) | 3000×2000 | 4000×2000 | 5000×2000 | 6000×2000 | 3000×2000 | 4000×2000 | 6000×2000 | 8000×2000 | 3000×2200 | 4000×2200 | 5000×2200 | 6000×2200 | 3000×2500 | 4000×2500 | 5000×2500 | 6000×2500 | 3000×2000 | 4000×2000 | 6000×2000 | 8000×2000 |

| Table T-slot(number-size ×spacings) | 11-22/180 | 11-22/180 | 11-22/180 | 11-22/180 | 11-28/200 | 11-28/200 | 11-28/200 | 11-28/200 | 11-22/180 | 11-22/180 | 11-22/180 | 11-22/180 | 13-22/180 | 13-22/180 | 13-22/180 | 13-22/180 | 11-28/200 | 11-28/200 | 11-28/200 | 11-28/200 |

| Workpiece loading capacity (T) | 10 | 13 | 16 | 19 | 16 | 20 | 28 | 30 | 7 | 9 | 14 | 20 | 8 | 10 | 15 | 20 | 16 | 20 | 28 | 30 |

| Table movement direction stroke (X-axis) | 3000 | 4000 | 5000 | 6000 | 3200 | 4200 | 6200 | 8200 | 3200 | 4200 | 5200 | 6200 | 3200 | 4200 | 5200 | 6200 | 3200 | 4200 | 6200 | 8200 |

| Spindle slide movement direction stroke (Y-axis) | 2300 | 2300 | 2300 | 2300 | 2800 | 2800 | 2800 | 2800 | 2500 | 2500 | 2500 | 2500 | 2700 | 2700 | 2700 | 2700 | 3300 | 3300 | 3300 | 3300 |

| Spindle up and down movement direction stroke (Z-axis) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000(1250) | 1000(1250) | 1000(1250) | 1000(1250) | 1000 | 1000 | 1000 | 1000 |

| Spindel nose to table surface (mm) | 250-1250 | 250-1250 | 250-1250 | 250-1250 | 200-1200 | 200-1200 | 200-1200 | 200-1200 | 250-1250 | 250-1250 | 250-1250 | 250-1250 | 220-1220 | 220-1220 | 220-1220 | 220-1220 | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Spindle speed (rpm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spindel drive | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Gear | Gear | Gear | Gear | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Belt/Gear/ZF | Gear | Gear | Gear | Gear |

| Spindle taper&diameter | BT50/Φ190 | BT50/Φ190 | BT50/Φ190 | BT50/Φ190 | BT50/Φ210 | BT50/Φ210 | BT50/Φ210 | BT50/Φ210 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Ø200 | BT50/Φ210 | BT50/Φ210 | BT50/Φ210 | BT50/Φ210 |

| Three-axis motor power(kw) | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 7/4.5/4.5 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 | 9/7.0/7.0 |

| Spindle motor power (kw) | 22 | 22 | 22 | 22 | 26 | 26 | 26 | 26 | 22 | 22 | 22 | 22 | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| Z-axis weighting method | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance | Oil Pressure + Nitrogen Balance |

| Three-axis cutting feed rate(mm/min) | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 | 10-7000 |

| Three-axis frapid traverse(mm/min) | 12/12/10 | 12/12/10 | 12/12/10 | 12/12/10 | 15/15/15 | 15/15/15 | 12/15/15 | 10/15/15 | 12/12/10 | 12/12/10 | 12/12/10 | 12/12/10 | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 | 15/15/15 | 15/15/15 | 12/15/15 | 10/15/15 |

| Positioning accuracy(mm) | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatability accuracy(mm) | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 | ±0.003/300 |

| Machine weight (T) | 32 | 35 | 40 | 42 | 34 | 38 | 45 | 53 | 37 | 43 | 47 | 55 | 41 | 45 | 51 | 58 | 35 | 39 | 46 | 54 |

| Machine dimension(Length×width×height) (mm) | 9000x5000x4800 | 11000x5000x4800 | 13000x5000x4800 | 15000x5000x4800 | 9000x5000x4800 | 11000x5000x4800 | 15000x5000x4800 | 19000x5000x4800 | 9000x5200x4800 | 11000x5200x4800 | 13000x5200x4800 | 15000×5200×4800 | 9000x5500x4800 | 11000x5500x4800 | 13000x5500x4800 | 15000×5500×4800 | 9000x5500x4800 | 11000x5500x4800 | 15000x5500x4800 | 19000x5500x4800 |

Previous article

Gantry machining center ( width 1220-2100mm)

Gantry machining center (width 3200-4800mm)

Next article