Shenzhen Shixinghong Precision Machinery Equipment Co., Ltd. / 粤ICP备11036526号 / Powered by www.300.cn

Page view:

Turning milling compound machine series

Quantity

-

+

Description

▌ Processing application

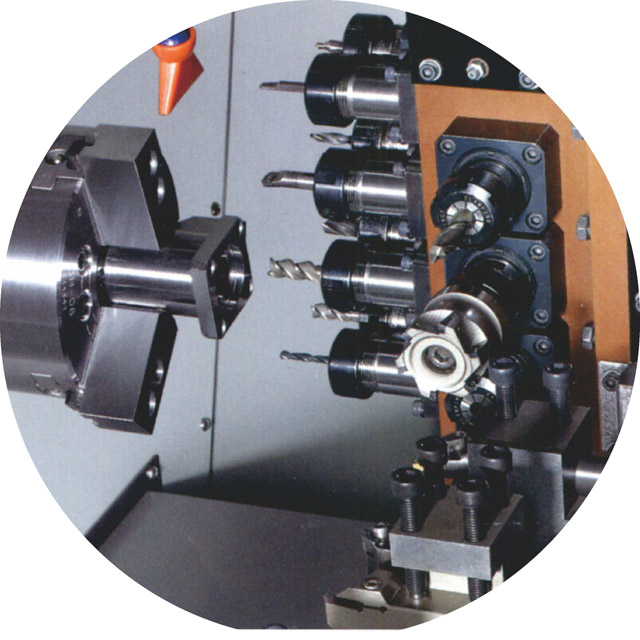

▌ Body structure details

|

Power head + Y axis + row knife combination |

Power head + Y axis + turret combination |

High-precision spindle + rotary cylinder with hydraulic clamping device |

Standard: neat and simple electrical cabinet |

▌ Technical Parameters

| Machine data / Model number | Units | TCK-46Y/46YD | TCK-52Y/52YD |

| Maximum turning diameter over bed | mm | Φ560 | Φ560 |

| Maximum workspace(length) | mm | 300 | 300 |

| Maximum machining diameter(Disk type) | mm | Φ400 | Φ400 |

| Spindle bore diameter | mm | Φ56 | Φ62 |

| Maximum bar diameter | mm | Φ45 | Φ52 |

| Spindle speed | rpm | 4000 | 3500 |

| Spindle cone type | ASA | A2-5 | A2-6 |

| Spindle motor power | kw | 7.5(servo) | 11(servo) |

| Bed structure (slant bed) | type | Resin sand castings | Resin sand castings |

| Guiding rail type | type | Linear | Linear |

| Tool turrets type | type | 8 or 12 positions(hydraulic/servo) | 8 or 12 positions(hydraulic/servo) |

| Tool specification | mm | 16×16/20×20 | 16×16/20×20 |

| X/Z /Y -axis motor power | kw | 2.4、2.4、1.7 | 2.4、2.4、1.7 |

| X-axis travel | mm | 1100 | 1100 |

| Z-axis travel | mm | 360 | 360 |

| Y-axis travel | mm | 240 | 240 |

| Fast displacement of X/Z- axis | m/min | 24 | 24 |

| Fast displacement of Y- axis | m/min | 15 | 15 |

| X/Z axis repeated positioning accuracy | mm | ±0.003 | ±0.003 |

| Processing accuracy | GB | IT6 | IT6 |

| Power head type | type | Gear type(dual motors) | Gear type(dual motors) |

| Power head chuck model | er | ER25 | ER25 |

| Number of power heads (end + side) | pcs | 3+3/4+4 | 3+3/4+4 |

| Power head maximum speed | rpm | 3000 | 3000 |

| Machine weight (approximately) | kg | 3300 | 3400 |

| Machine size(Length×width×height) | mm | 2050x1800x2100 | 2050x1800x2100 |