Shenzhen Shixinghong Precision Machinery Equipment Co., Ltd. / 粤ICP备11036526号 / Powered by www.300.cn

Tail stock machine series

▌ Processing application

Automobile, aviation, machinery manufacturing.

▌ Body structure details

|

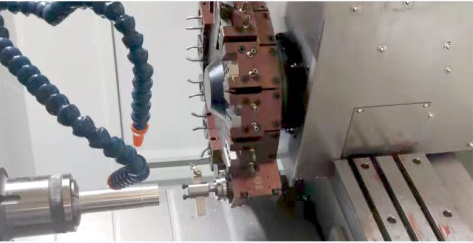

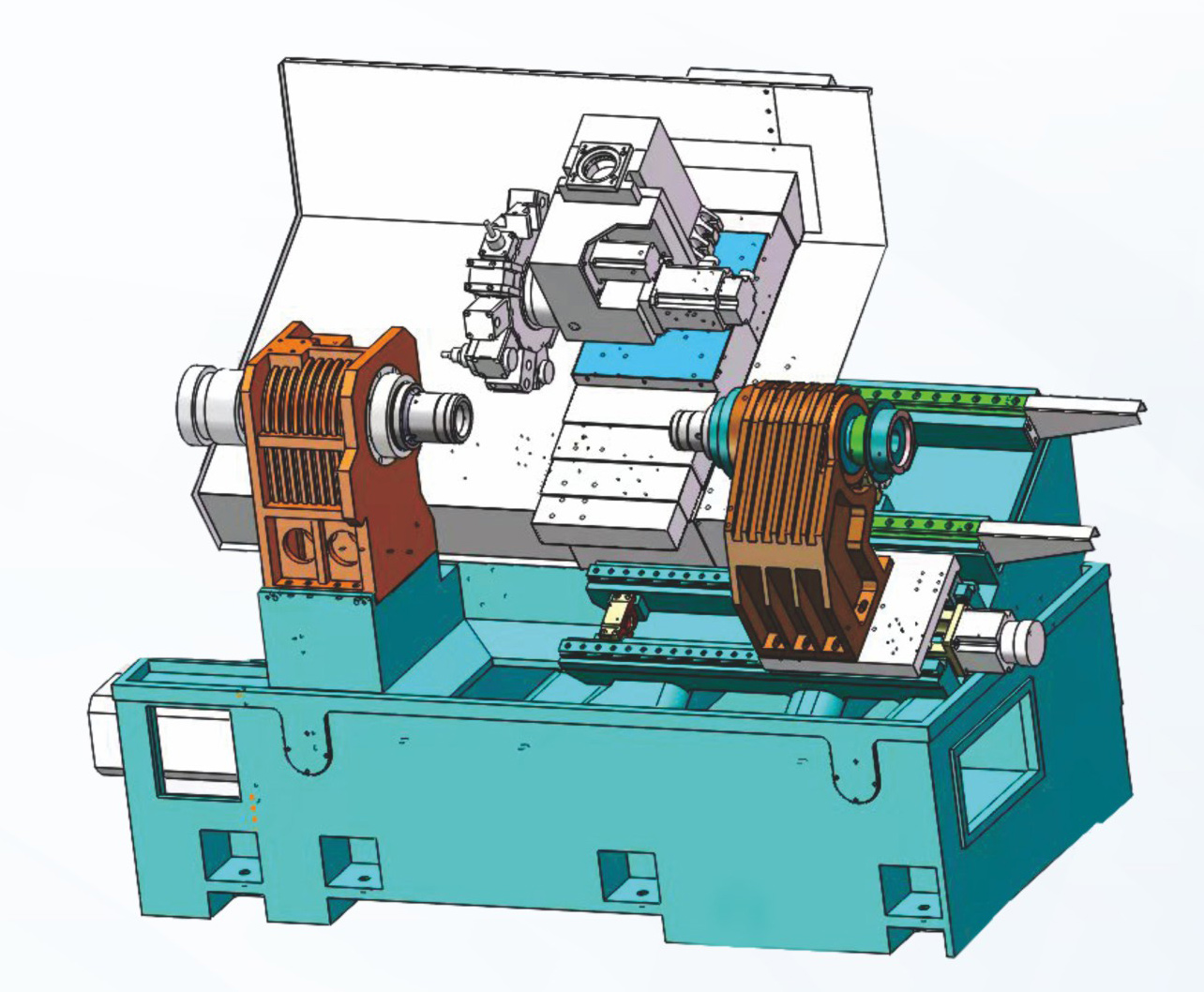

Servo power turret +y axis

|

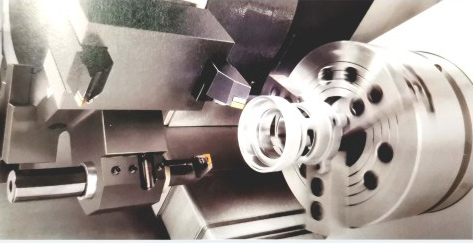

Servo power turret +y axis + tailstock

|

|

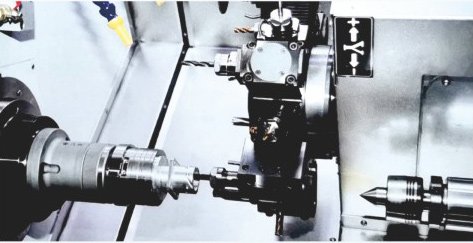

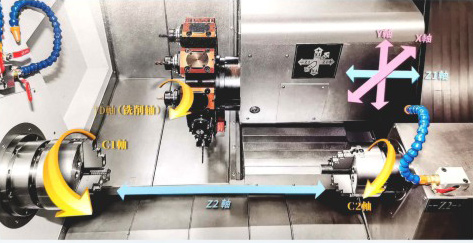

Servo power turret +y axis + double spindle

|

Servo power turret +y axis + back axis machining

|

|

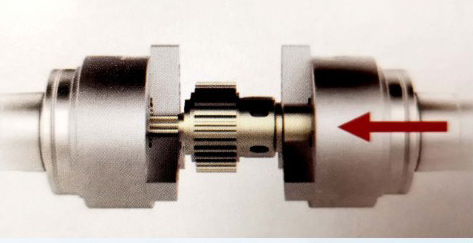

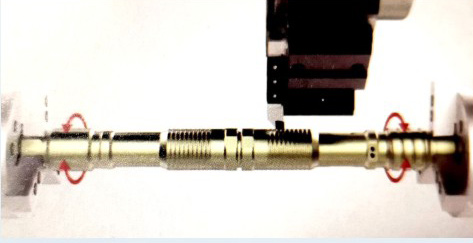

Under the synchronous control of equal speed, the auxiliary spindle accurately receives the workpiece from the spindle, |

Higher machining accuracy can be obtained by machining long workpieces (such as mandrels) through the auxiliary spindle. Both ends of the workpiece are clamped and supported by the main shaft and the auxiliary main shaft at the same time to carry out the precision machining of the middle section of the workpiece, |

▌ Technical Parameters

| Machine data / Model number | Units | TCK-46MY | TCK-46MYW | TCK-52MYW | TCK-52YDW |

| Maximum turning diameter over bed | mm | Φ560 | Φ620 | Φ620 | Φ600 |

| Maximum machining diameter(Disk type) | mm | Φ400 | Φ500 | Φ500 | Φ450 |

| Maximum swing diameter over the table | mm | Φ200 | Φ320 | Φ320 | Φ210 |

| Maximum processing length | mm | 300 | 450 | 450 | 500 |

| Spindle cone type | A2-5 | A2-5 | A2-6 | A2-6 | |

| Grip type | Collet/6" chuck | Collet/6" chuck | Collet/8" chuck | Collet/8" chuck | |

| Spindle bore diameter | mm | Φ56 | Φ56 | Φ66 | Φ66 |

| Maximum bar diameter | mm | Φ45 | Φ45 | Φ52 | Φ52 |

| Spindle speed | rpm | 4500 | 4500 | 4000 | 4000 |

| Spindle motor power | kw | 7.5(servo) | 7.5(servo) | 11(servo) | 11/15(servo) |

| Spindle index repeated positioning accuracy | ° | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| X/Y/Z-axis travel | mm | 210/100/360 | 270/80/450 | 270/80/450 | 250/80/610 |

| Fast displacement of X/Y/Z- axis | m/min | 30/20/30 | 20/15/20 | 20/15/20 | 30/20/30 |

| X/Y/Z-axis repeated positioning accuracy | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 |

| X/Z /Y -axis motor power | kw | 2.4/1.7/2.4 | 2.4/1.7/2.4 | 2.4/2.4/2.4 | 2.4/2.4/2.4 |

| Tool-rest type | type | 12/15 positions | 12/15 positions | 12 positions | 12 positions |

| Square/boring-tool specifications | mm | 25*25/Φ32 | 25*25/Φ32 | 25*25/Φ32 | 25*25/Φ32 |

| Turret motor power | kw | 1 | 1 | 1 | 1 |

| Dynamic servo motor power | kw | 3.1 | 3.1 | 3.1 | 3.1 |

| Dynamic head specifications | BMT40 | BMT40 | BMT45 | BMT55 | |

| Tail-stock sleeve diameter | mm | / | 68 | 68 | 80 |

| Maximum tail-stock sleeve stroke | mm | / | / | / | 80 |

| Maximum tail-stock stroke | mm | / | 450 | 450 | 450 |

| Tail-stock sleeve type | / | Hydraulic | Hydraulic | Hydraulic | |

| Tail-stock sleeve taper | MT | / | Mohs 5# | Mohs 5# | Mohs 5# |

| Hydraulic motor power | kw | 1.5 | 1.5 | 1.5 | 1.5 |

| Pump motor power | kw | 0.75 | 0.75 | 0.75 | 0.75 |

| Machine weight (approximately) | kg | 3400 | 4200 | 4300 | 4600 |

| Machine size(Length×width×height) | mm | 2050×1800×2100 | 2350x1750x2100 | 2350x1750x2100 | 2700×2100×2300 |

| Machine data / Model number | Units | TCK-52MYS(Dual-spindle) |

| Maximum turning diameter over bed | mm | Φ620 |

| Maximum machining diameter(Disk type) | mm | Φ500 |

| Maximum swing diameter over the table | mm | Φ320 |

| Maximum processing length | mm | 550 |

| Spindle cone type | A2-6 | |

| Grip type | Collet/8" chuck | |

| Spindle bore diameter | mm | Φ65 |

| Maximum bar diameter | mm | Φ52 |

| Spindle speed | rpm | 4000 |

| Spindle motor power | kw | 15(servo) |

| Spindle index repeated positioning accuracy | ° | ±0.005 |

| X/Y/Z/Z2-axis travel | mm | 270/±50/600/500 |

| Fast displacement of X/Y/Z- axis | m/min | 20/15/20 |

| X/Y/Z-axis repeated positioning accuracy | mm | ±0.003 |

| X/Z /Y -axis motor power | kw | 3.9/2.4/3.9 |

| Tool-rest type | type | 12 positions |

| Square/boring-tool specifications | mm | 25*25/Φ40 |

| Turret swirling motor power | kw | 1.0 |

| Dynamic servo motor power | kw | 3.1 |

| Dynamic head specifications | BMT45(55)/ER25/ER32 | |

| Vice-spindle type | A2-5 electric spindle | |

| Vice-spindle travel | mm | 500 |

| Vice-spindle cone type | A2-5 | |

| Vice-spindle Grip type | 筒夹/5寸卡盘 | |

| Vice-Spindle bore diameter | mm | Φ56 |

| Maximum bar diameter | mm | Φ45 |

| Vice-spindle speed | rpm | 6000 |

| Vice-spindle power | kw | 11 |

| X/Y/Z-axis repeated positioning accuracy | mm | ±0.005 |

| X/Y/Z-axis motor power | kw | 2.4 |

| Machine weight (approximately) | kg | 5000 |

| Machine size(Length×width×height) | mm | 2700×1750×2250 |